Project Customization Options

Your Vision, Our Craftsmanship

Fabric Materials

Customers have the option to provide their own materials (referred to as Customers Own Material, or COM). Alternatively, we source and provide a warranty for the materials supplied by QA Group. Should you wish, you can request the return of any leftover materials. Otherwise, we retain them for three months following the completion of the order, allowing for any potential future needs before considering donation or repurposing.

Direction & Placement

If the fabric features a pattern or print rather than a plain solid, please confirm a direction at the time of fabric approval. “Railroaded” is typically the preferred direction to minimize scraps; it is used as default if not otherwise specified by the client. However, if you’re unsure, don’t hesitate to consult your sales representative. The direction of the fabric can significantly impact the overall appearance of the upholstered item.

Fabric pattern matching is typically done using a commercial match standard, ensuring a pleasing appearance overall. It is used as default if not otherwise specified by the client. This approach allows us to adhere to the quoted timeframe without additional charges. Please specify if an exact pattern match is required for your project.

For velvet or velvet-like materials, please specify the direction for the nap/rub to run.

If you’re uncertain about selecting the fabric direction or considering paying extra for an exact pattern match, QA Group can make an informed decision to ensure the best possible appearance while also considering optimal material yield. This is used as default if not otherwise specified by the client.

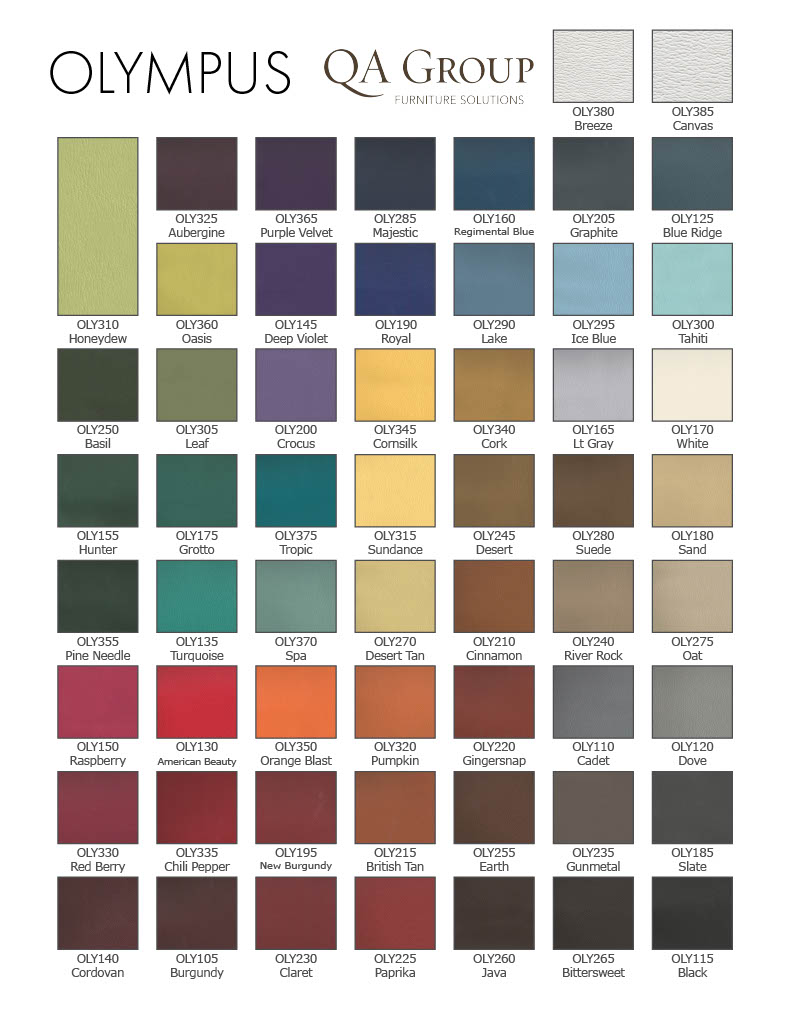

Fabric & Leather

We’ve established strong partnerships with our esteemed fabric and leather suppliers, fostering excellent relationships. Our trusted vendors include Architex, Arc-Com, Anzea, Burch, Kravet, Mayer Fabrics, Momentum, Pallas, Stinson, Garrett Leather, Designtex, Maharam, Knoll, Carnegie, Stinson, Camira, Spinneybeck, HBF Textiles, and numerous others.

Vinyl

We’ve curated a premier assortment of vinyl, readily available and frequently chosen for commercial booths and chairs. Teaming up with Keyston Bros, we ensure durable vinyl choices for our commercial furniture offerings. Samples available upon request.

Finishing Materials

Custom Staining for Wood Materials

Discover an array of refined stain colors to elevate the appearance of your wooden item. Different wood species showcase diverse shades and tones, resulting in variations in how stains of the same color appear across species. Moreover, digital representations may differ on different devices. Don’t hesitate to request samples to view the colors in person. With a variety of stain options available in different tints and colors, customization is at your fingertips.

Additionally, we offer the option for custom color matching or painting instead of using a wood stain. For this, QA Group will require two control samples.

Before proceeding, we require client confirmation on the finish color and sheen, as well as the direction of the veneer or p-lam, if applicable. Please note that our standard clear natural finishes have a 20% sheen.

Wood Finishes

We utilize solid hardwood plywood. Additionally, we provide priced alternatives for marine grade, FSC-certified, and fire-rated wood products.

All laminates and veneers utilized in our projects are custom ordered to meet the specific requirements of each job. We frequently collaborate with Wilsonart and Formica products. For any specialized products, please expect additional time for procurement.

Design Details: Customization Options

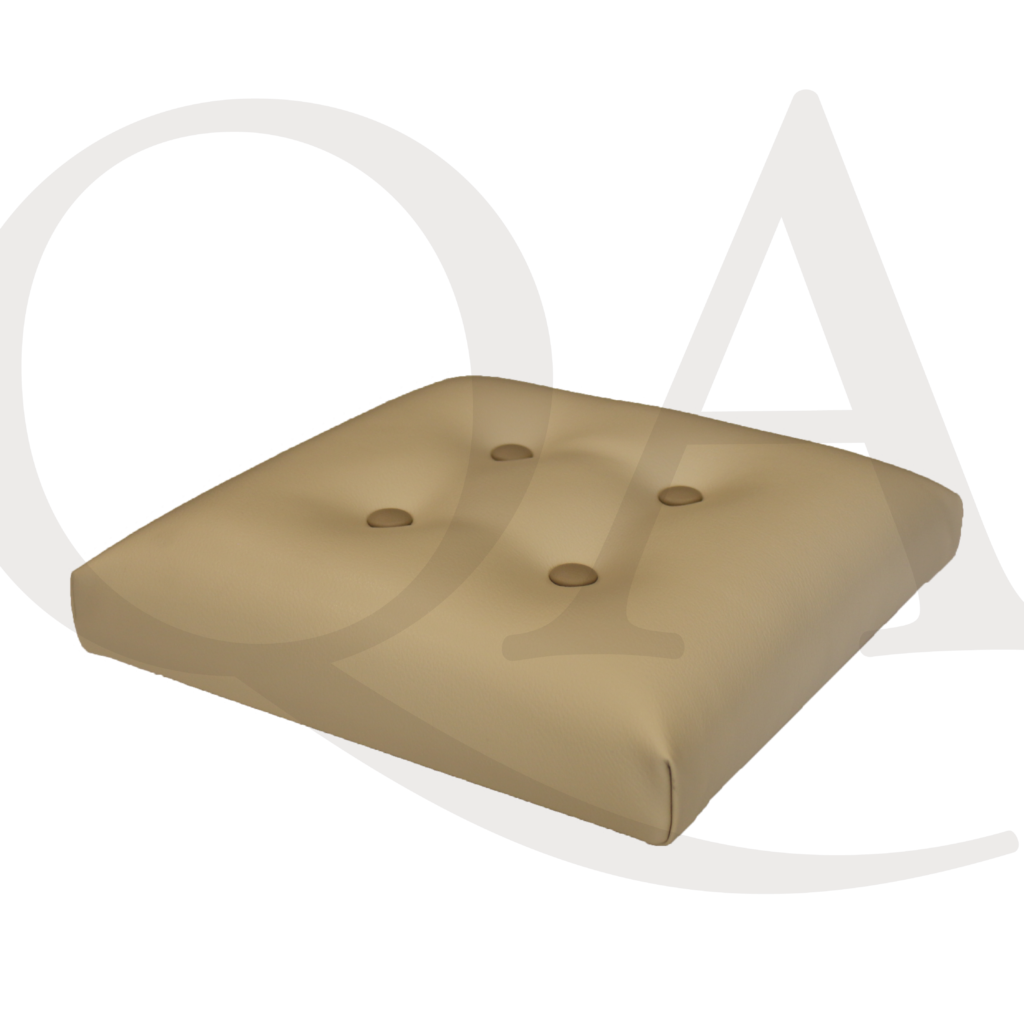

Tufting (shown on a staple wrap panel)

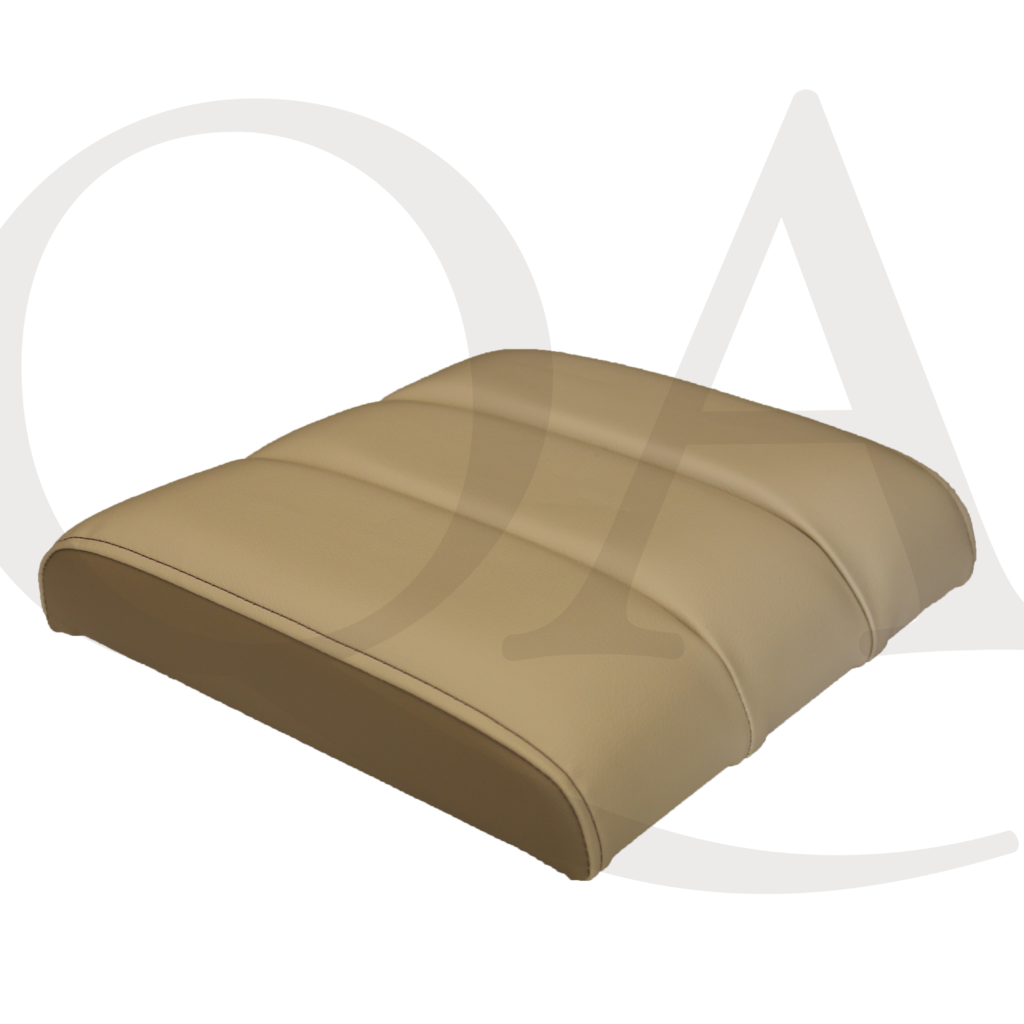

Channeling

Channeling refers to creating linear indentations or grooves on the surface of upholstery, either vertically or horizontally. This technique adds visual interest and can complement the overall design scheme.

Both vertical and horizontal channeling options are offered, though seats are limited to vertical channels only.

Additionally, bolster channels are available, featuring a more pronounced radius.

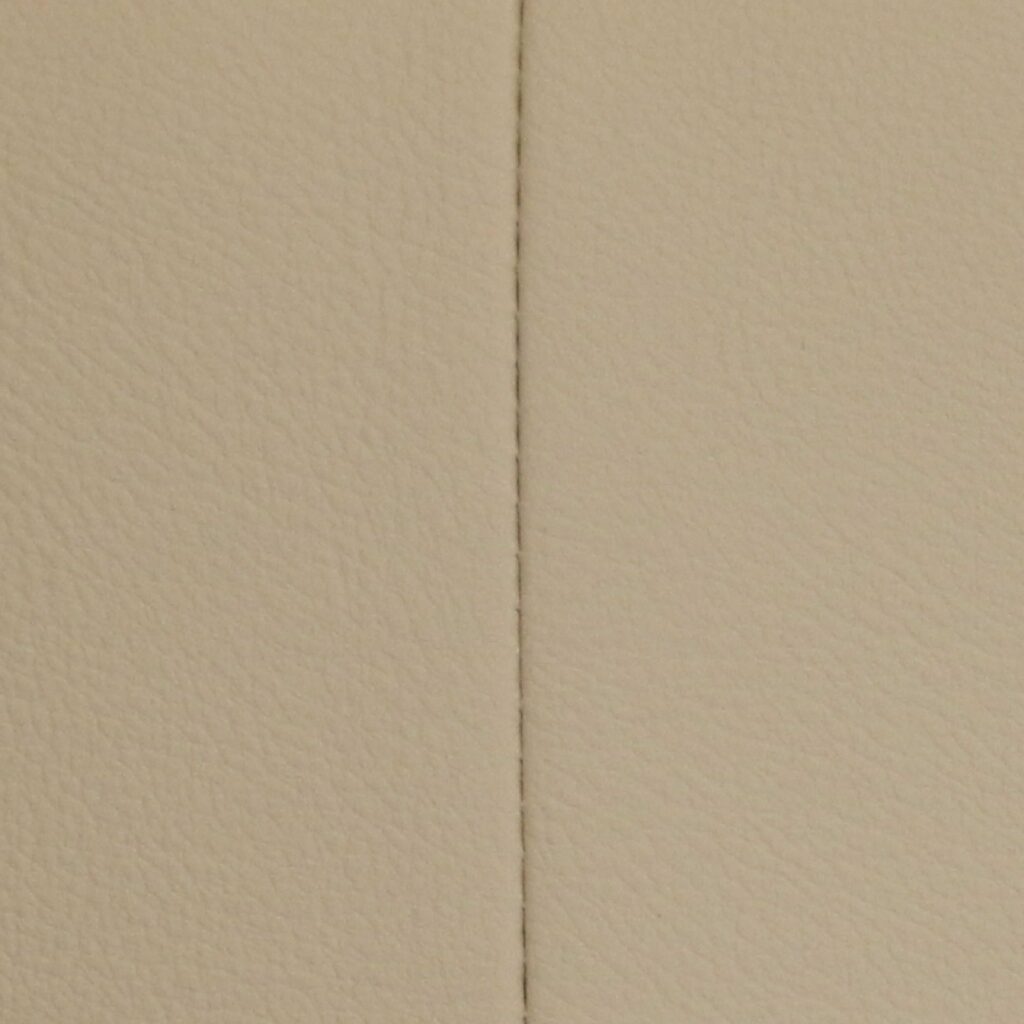

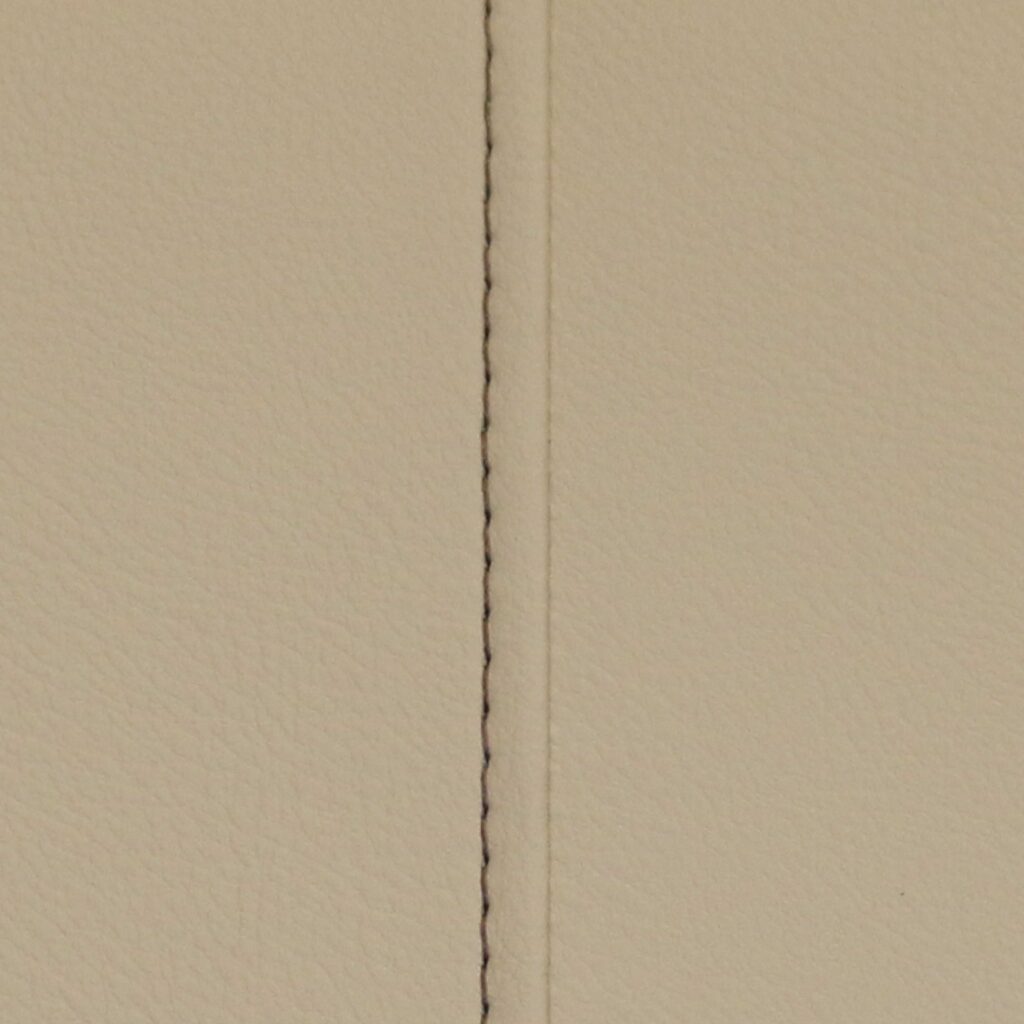

Stitching

Our stitching options include a plain seam (without top stitching), single top stitch, or double top stitching for added detailing and durability.

For commercial projects, our default choice is a single top stitch. Our standard thread color will closely match the material being sewn, unless specified otherwise. Please note that our samples demonstrate contrasting thread to highlight stitching details.

Stitched channeling and stitched diamond tufting differ from traditional methods, providing an updated visual appeal. Unlike conventional tufting or channeling, they lack folded or pulled tucks or buttons, resulting in a clean, modern appearance.

Plain Seam

Single Top Stitch

Double Top Stitch

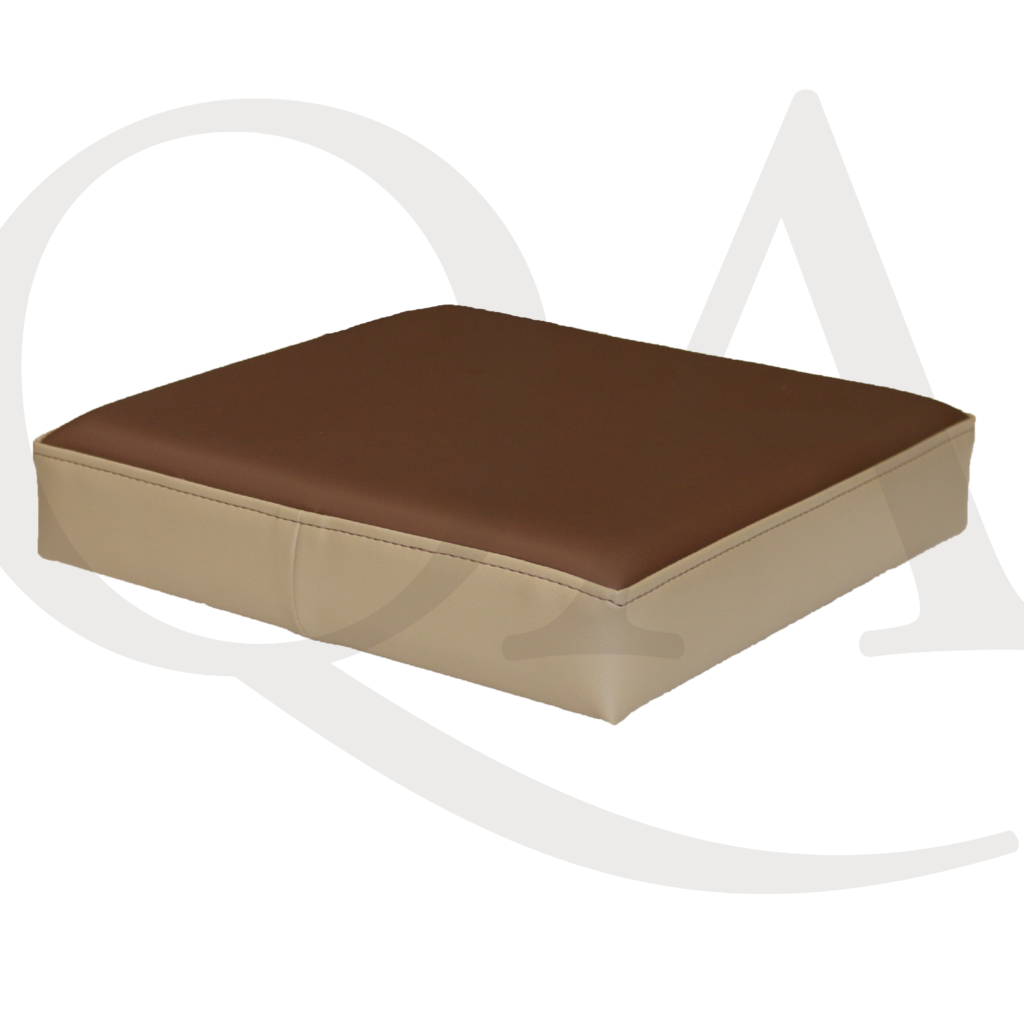

Panel Upholstery Style

Panel Model

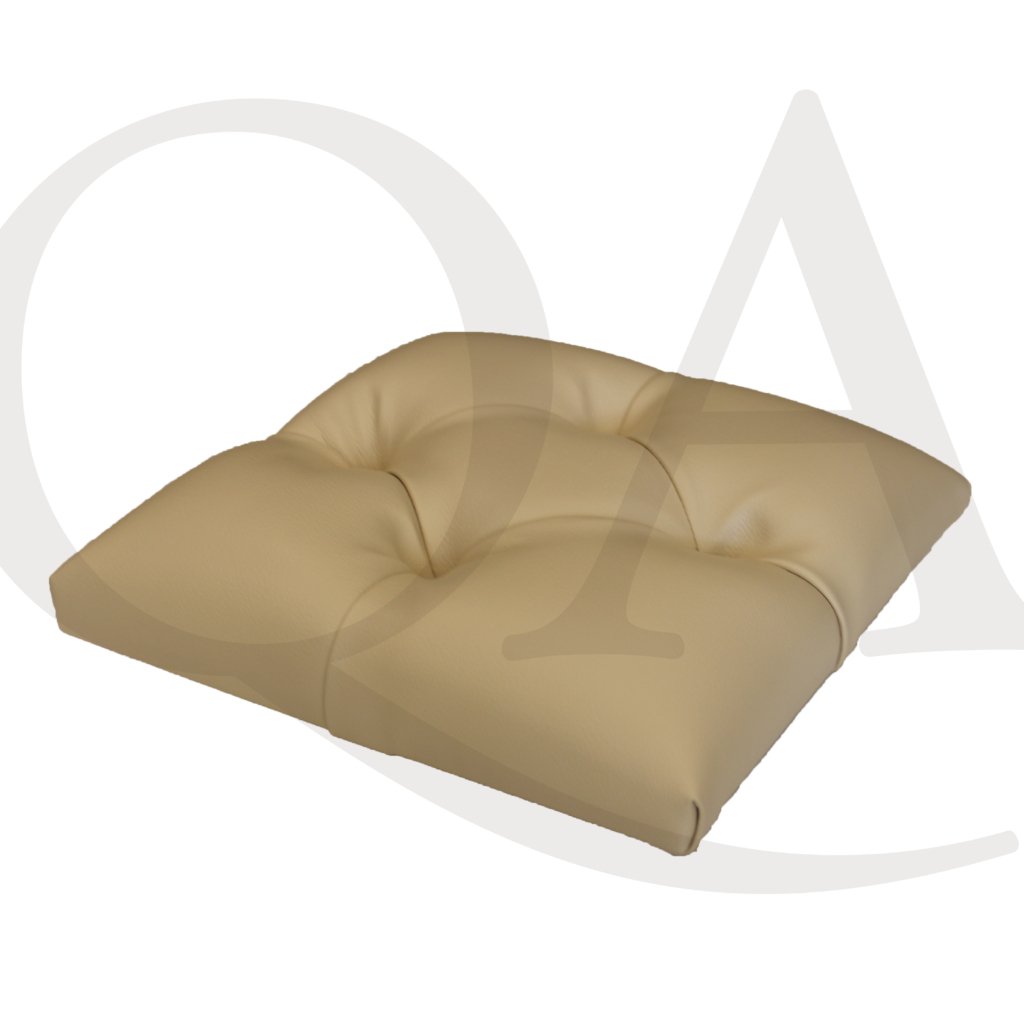

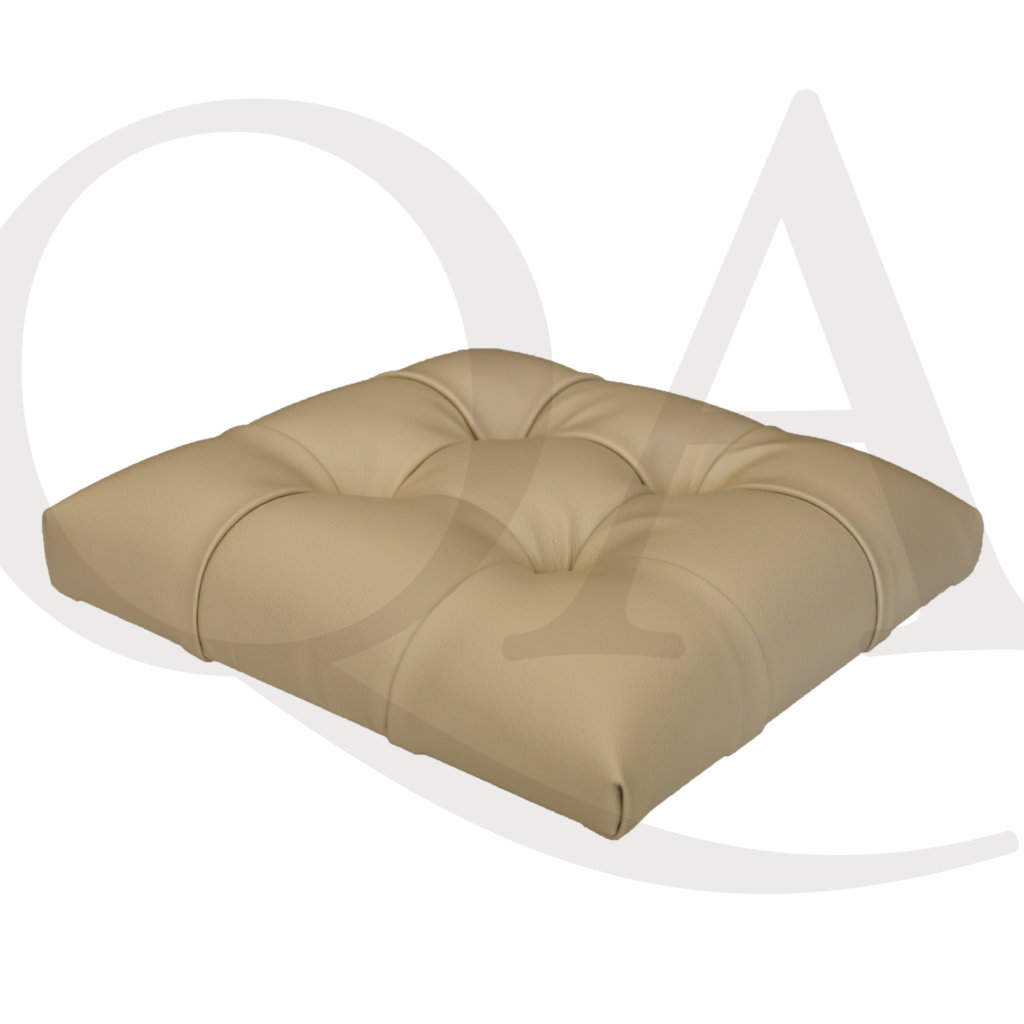

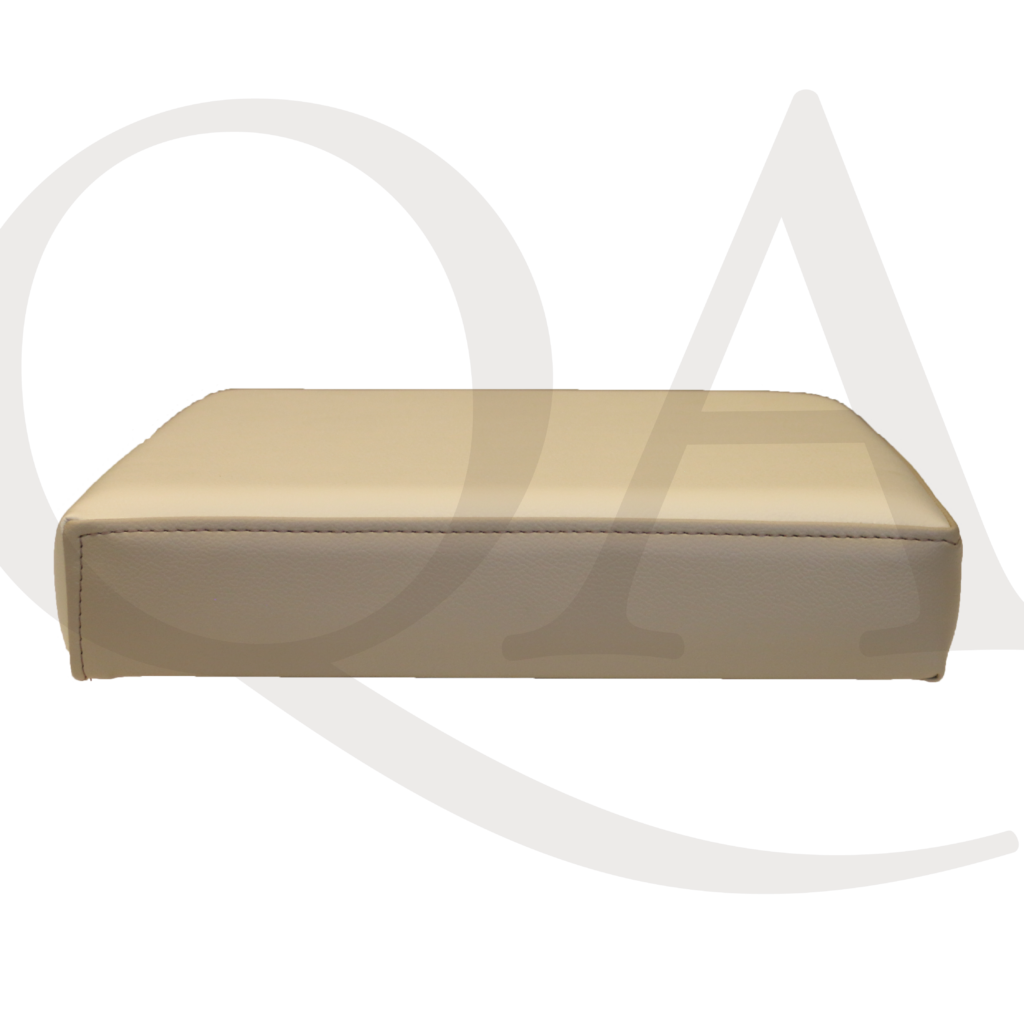

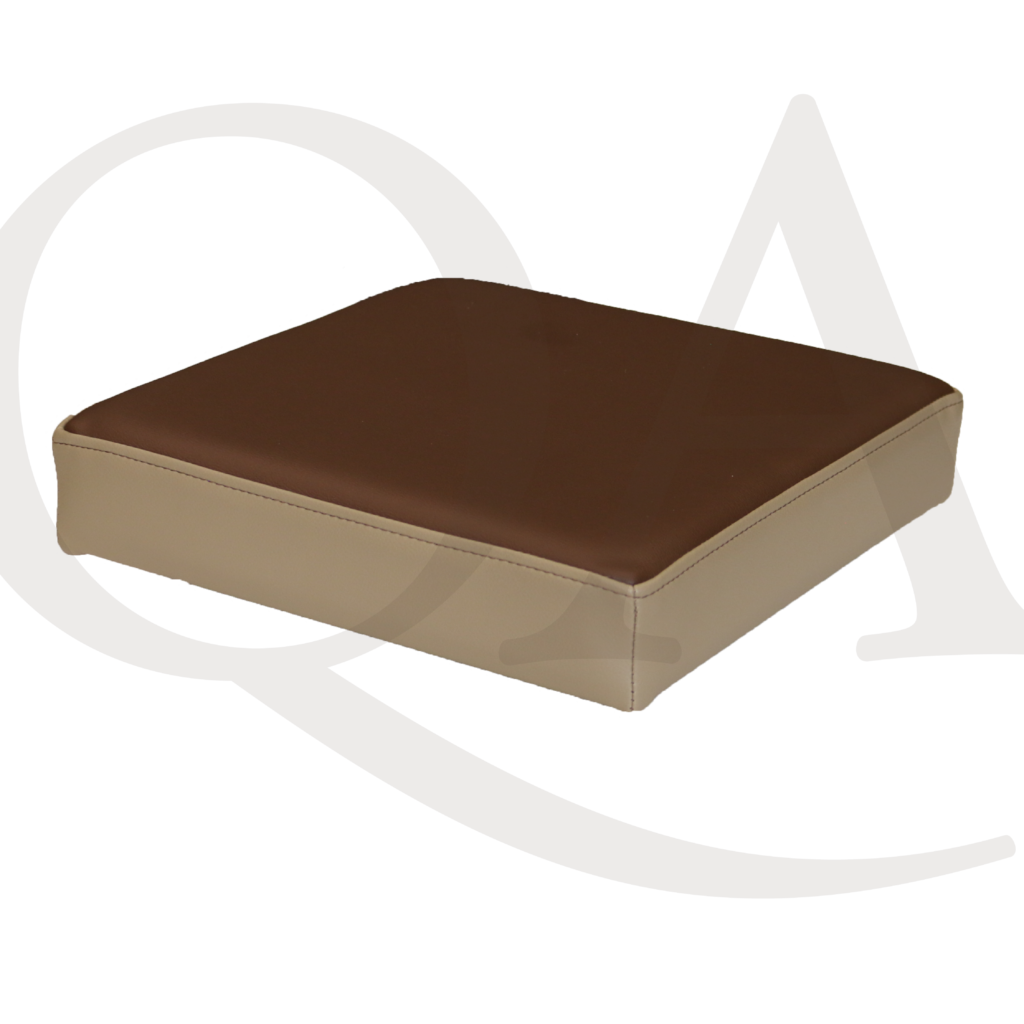

Cushion Fill

Springs: We provide the option of utilizing no-sag sinuous springs, which are accompanied by a layer of foam and Dacron for added comfort and support. It’s important to note that our standard practice is to refrain from springing our back options. Additionally, any item intended to be sprung must have a minimum thickness of 6 inches to ensure proper functionality and durability.

Foam: We offer standard commercial grade or high resiliency foam. If necessary, sit-test samples are available to help you make an informed decision. Regardless of the foam type chosen, it will always be wrapped in Dacron for added comfort and durability. Should you desire additional layers of Dacron, they can be included upon request to enhance the plushness of your upholstery.